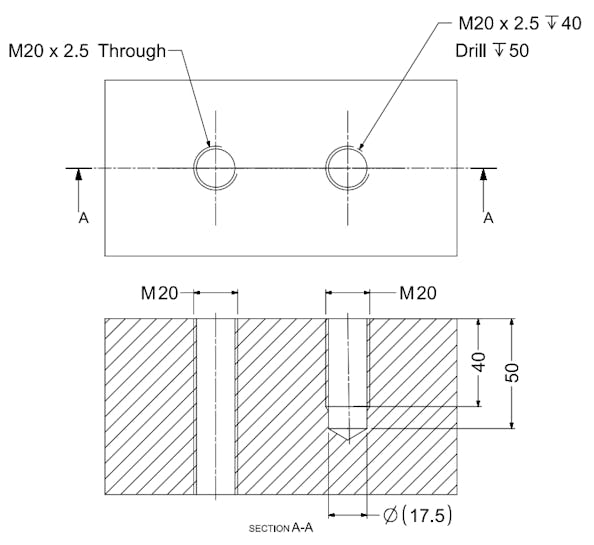

Blind Hole What Does It Mean . a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. a hole that does not go through the whole workpiece is called a blind hole. a blind hole is a carefully designed hole that only partially penetrates the material. This deliberate depth is usually less than the. a blind hole is a hole that does not go all the way through a part. holes that go all the way through the component are known as through holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. A blind hole goes to a specified depth and stops. Holes that do not go completely through the material are known as blind holes. It ends at a certain depth within the.

from www.xometry.com

This deliberate depth is usually less than the. A blind hole goes to a specified depth and stops. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. a hole that does not go through the whole workpiece is called a blind hole. a blind hole is a hole that does not go all the way through a part. It ends at a certain depth within the. holes that go all the way through the component are known as through holes. Holes that do not go completely through the material are known as blind holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining.

What Are Blind Holes in Engineering and Machining? Xometry

Blind Hole What Does It Mean It ends at a certain depth within the. holes that go all the way through the component are known as through holes. This deliberate depth is usually less than the. It ends at a certain depth within the. a blind hole is a hole that does not go all the way through a part. a hole that does not go through the whole workpiece is called a blind hole. a blind hole is a carefully designed hole that only partially penetrates the material. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. Holes that do not go completely through the material are known as blind holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. A blind hole goes to a specified depth and stops.

From eureka.patsnap.com

Blind hole electric pulse machining structure and operation method Blind Hole What Does It Mean Holes that do not go completely through the material are known as blind holes. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. This deliberate depth is usually less than the. a blind hole is a hole that does not go all the way through a part. A. Blind Hole What Does It Mean.

From www.machinistguides.com

Blind Holes All About Machinist Guides Blind Hole What Does It Mean a blind hole is a carefully designed hole that only partially penetrates the material. It ends at a certain depth within the. This deliberate depth is usually less than the. a hole that does not go through the whole workpiece is called a blind hole. A blind hole goes to a specified depth and stops. holes that. Blind Hole What Does It Mean.

From www.cnccookbook.com

Blind Hole Tapping Secrets [ Stop Breaking Taps! ] Blind Hole What Does It Mean a blind hole is a hole that does not go all the way through a part. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. A blind hole goes to a specified depth and stops. a hole that does not go through the whole workpiece is called. Blind Hole What Does It Mean.

From www.machinistguides.com

Guide to Holes on Blueprints [Types, Symbols & Features] Machinist Guides Blind Hole What Does It Mean a blind hole is a carefully designed hole that only partially penetrates the material. a hole that does not go through the whole workpiece is called a blind hole. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. It ends at a certain. Blind Hole What Does It Mean.

From electrical-information.com

Difference Between Throughhole, Blind Via, Buried Via, and Land Blind Hole What Does It Mean a blind hole is a carefully designed hole that only partially penetrates the material. Holes that do not go completely through the material are known as blind holes. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite end of the workpiece material. a hole that does not go through the whole workpiece. Blind Hole What Does It Mean.

From threadingtoolsguide.com

Difference between through hole and blind hole on threadingtools giude Blind Hole What Does It Mean This deliberate depth is usually less than the. holes that go all the way through the component are known as through holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. a hole that does not go through the whole workpiece is called a blind. Blind Hole What Does It Mean.

From www.flickr.com

DSC05209 A shallow blind hole is drilled alongside the mai… Flickr Blind Hole What Does It Mean It ends at a certain depth within the. holes that go all the way through the component are known as through holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. a blind or pocket hole is a cavity/hole that doesn’t lead to the opposite. Blind Hole What Does It Mean.

From www.sansmachining.com

Understanding Blind Holes in Machining SANS Blind Hole What Does It Mean A blind hole goes to a specified depth and stops. Holes that do not go completely through the material are known as blind holes. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. a blind hole is a hole that does not go all the way. Blind Hole What Does It Mean.

From www.madearia.com

What are the different types of holes in engineering? Blind Hole What Does It Mean in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. This deliberate depth is usually less than the. a hole that does not go through the whole workpiece is called a blind hole. a blind hole is a hole that does not go all. Blind Hole What Does It Mean.

From www.slideserve.com

PPT Holes PowerPoint Presentation, free download ID2107959 Blind Hole What Does It Mean in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. A blind hole goes to a specified depth and stops. this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. a blind hole. Blind Hole What Does It Mean.

From www.cutwel.co.uk

How to select the correct tap for your job Cutwel Ltd Blind Hole What Does It Mean Holes that do not go completely through the material are known as blind holes. a blind hole is a hole that does not go all the way through a part. a blind hole is a carefully designed hole that only partially penetrates the material. a hole that does not go through the whole workpiece is called a. Blind Hole What Does It Mean.

From solidcam.help

Introduction and Basic Concepts Blind Hole What Does It Mean This deliberate depth is usually less than the. a blind hole is a hole that does not go all the way through a part. a hole that does not go through the whole workpiece is called a blind hole. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not. Blind Hole What Does It Mean.

From www.researchgate.net

Drilling process (a) blind holes (b) through holes [10]. Download Blind Hole What Does It Mean a blind hole is a carefully designed hole that only partially penetrates the material. This deliberate depth is usually less than the. a hole that does not go through the whole workpiece is called a blind hole. holes that go all the way through the component are known as through holes. in engineering drawing and machining,. Blind Hole What Does It Mean.

From www.linkedin.com

What is the difference between through hole, buried hole, and blind hole? Blind Hole What Does It Mean holes that go all the way through the component are known as through holes. a hole that does not go through the whole workpiece is called a blind hole. This deliberate depth is usually less than the. Holes that do not go completely through the material are known as blind holes. this article will explore what a. Blind Hole What Does It Mean.

From www.slideserve.com

PPT Chapter 10 cont. PowerPoint Presentation, free download ID1984589 Blind Hole What Does It Mean a blind hole is a carefully designed hole that only partially penetrates the material. Holes that do not go completely through the material are known as blind holes. in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. a blind hole is a hole. Blind Hole What Does It Mean.

From okdor.com

What is the Difference Between Blind Holes and Through Holes? Blind Hole What Does It Mean this article will explore what a blind hole is, how to make blind holes, and why they are essential in machining. Holes that do not go completely through the material are known as blind holes. It ends at a certain depth within the. in engineering drawing and machining, a blind hole (also known as a pocket or closed. Blind Hole What Does It Mean.

From toolsmechanism.com

How to Mark Blind Holes for Drilling? Tools Mechanism Blind Hole What Does It Mean in engineering drawing and machining, a blind hole (also known as a pocket or closed hole) does not pass through the entire thickness. This deliberate depth is usually less than the. a blind hole is a carefully designed hole that only partially penetrates the material. a blind or pocket hole is a cavity/hole that doesn’t lead to. Blind Hole What Does It Mean.

From samhakes.com

Types of Holes The Complete Guide The Engineer's Bible (2023) Blind Hole What Does It Mean A blind hole goes to a specified depth and stops. Holes that do not go completely through the material are known as blind holes. holes that go all the way through the component are known as through holes. a blind hole is a carefully designed hole that only partially penetrates the material. in engineering drawing and machining,. Blind Hole What Does It Mean.